Revolutionizing Industrial Equipment Manufacturing: The Power of 3D Printing in Creating Exceptional Street Sweeper Vehicles

Introduction to the Future of Business and Manufacturing Innovation

In an era marked by rapid technological advancements and increasing demand for efficient, sustainable, and cost-effective infrastructure maintenance, the manufacturing of street sweeper vehicles is undergoing a profound transformation. Central to this evolution is the integration of 3D printing technology—also known as additive manufacturing—which offers unparalleled capabilities in designing, prototyping, and producing complex components with remarkable precision. Businesses like cepsansweepers.com are pioneering this innovative approach, positioning themselves at the forefront of the industry.

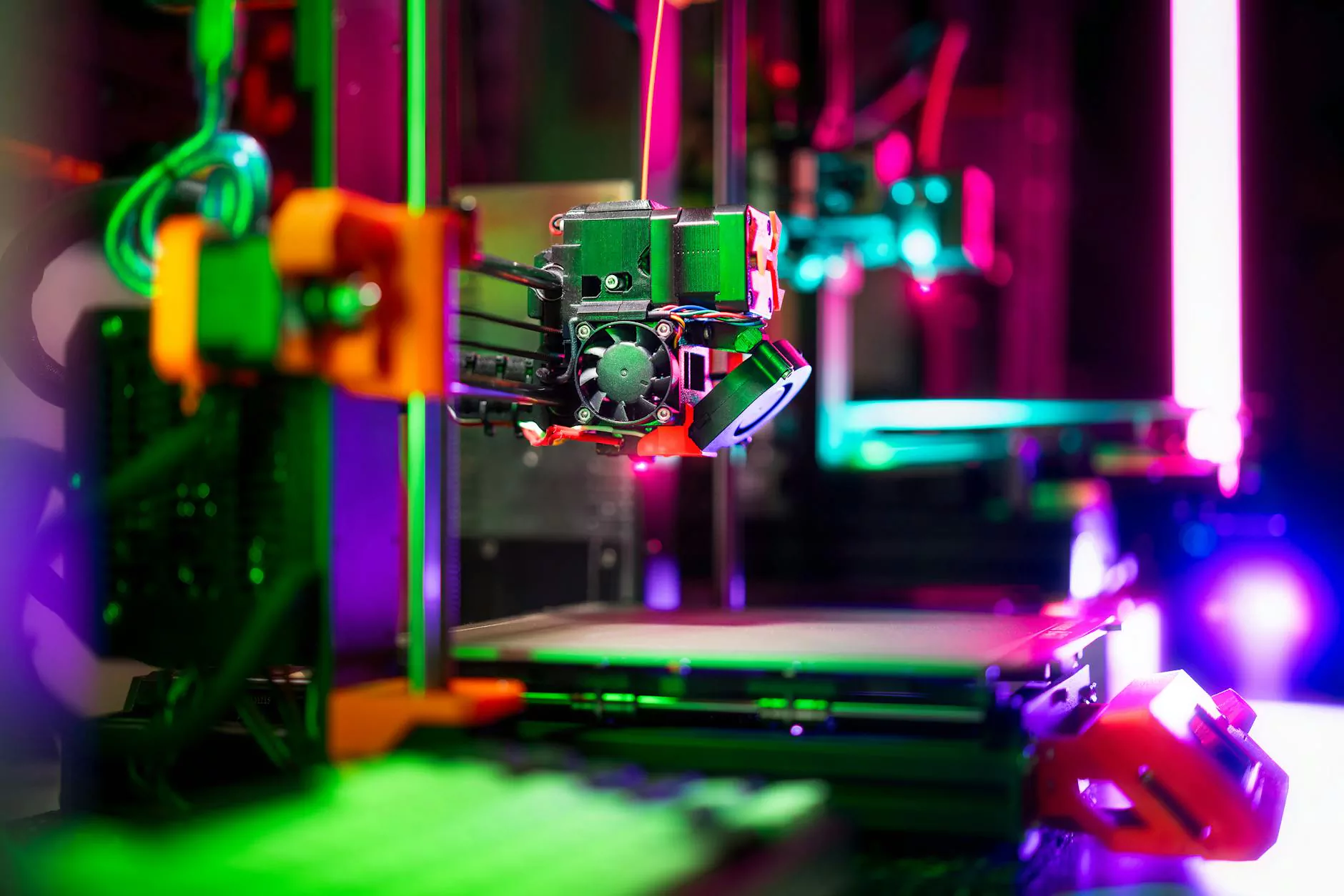

Understanding 3D Printing: The Technology Powering Modern Business Solutions

The technology of 3D printing involves creating three-dimensional objects from digital models by adding material layer by layer. This method contrasts sharply with traditional subtractive manufacturing processes, enabling rapid prototyping, customization, and the production of complex geometries that were previously impossible or too costly to manufacture. The benefits for manufacturing large-scale machinery like street sweeper vehicles are immense, including reduced lead times, lower costs, and increased design flexibility.

The Role of 3D Printing in Manufacturing Street Sweeper Vehicles

Manufacturing street sweeper vehicles demands precision engineering, durability, and the ability to adapt quickly to changing customer needs. Incorporating 3D printing into this process has revolutionized how manufacturers develop and produce these essential urban maintenance machines. Key advantages include:

- Rapid Prototyping: Accelerates the development cycle by enabling fast creation of functional prototypes for testing and evaluation.

- Component Optimization: Allows for the design of lightweight, yet durable, parts that improve overall vehicle efficiency and maneuverability.

- Customization and Flexibility: Facilitates tailored solutions for specific urban environments or client requirements without the need for costly retooling.

- Cost Reduction: Minimizes material waste and reduces manufacturing steps, leading to significant cost savings.

- Supply Chain Simplification: Enables on-demand production of spare parts, reducing downtime and inventory costs.

Innovative Materials and Techniques in 3D Printing for Heavy Machinery

Modern 3D printing utilizes a variety of advanced materials compatible with heavy-duty applications, including high-strength thermoplastics, metal alloys such as aluminum, stainless steel, and even composite materials. The choice of material depends on the component’s function, load-bearing requirements, and environmental conditions. Techniques such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Fused Deposition Modeling (FDM) empower manufacturers to produce parts that meet safety and performance standards.

Case Studies: Success Stories of 3D Printing in Street Sweeper Vehicle Development

Customized Brush Assembly Components

A leading manufacturer integrated 3D-printed parts in the brush assembly mechanism, dramatically reducing weight and increasing wear resistance. These advancements resulted in longer service intervals and reduced maintenance costs.

Innovative Hydraulics and Control Modules

Using metal additive manufacturing, complex hydraulic components with integrated cooling channels were produced, enhancing efficiency and reliability of the hydraulic systems in street sweeper vehicles.

Rapid Production of Replacement Parts

During a demonstration project, a fleet of street sweepers experiencing component failure benefited from on-site 3D printing of replacement parts, massively reducing downtime and logistic costs.

The Business Advantages of Adopting 3D Printing for Manufacturing Street Sweeper Vehicles

For companies like cepsansweepers.com, embracing 3D printing translates into concrete business benefits, including:

- Enhanced Competitive Edge: Keeping pace with technological innovation ensures market leadership and customer satisfaction.

- Cost Optimization: Significant savings in prototyping and small-batch production make the entire process more economical.

- Faster Time-to-Market: Accelerating the design-to-production cycle allows for quick rollouts of new features and models.

- Environmental Sustainability: Reduced waste and energy consumption align with modern eco-conscious manufacturing practices.

- Improved Quality Control: Digital workflows and in-house additive manufacturing enable better oversight and consistent quality.

Environmental and Regulatory Considerations in 3D Printing of Heavy Equipment

The sustainability aspect of 3D printing aligns well with increasing environmental regulations. Using recyclable materials and reducing waste are fundamental, as are efforts to achieve certifications such as ISO 14001. Moreover, additive manufacturing can enable the production of lightweight parts that contribute to lower emissions during operation, supporting greener urban infrastructure management.

Future Trends in 3D Printing for Street Sweeper Vehicles Manufacturing

The future promises exciting developments, such as:

- Multi-Material Printing: Combining metals, plastics, and composites in a single component for enhanced functionality.

- Large-Scale Additive Manufacturing: Growing capabilities to produce larger parts or complete assemblies that fit the scale of industrial machinery.

- Automation and Artificial Intelligence: Integrating AI-driven design and manufacturing processes for optimal performance and customization.

- Smart Materials: Utilizing materials that respond to environmental stimuli, opening avenues for adaptive and intelligent vehicle components.

Partnering with Industry Leaders: How cepsansweepers.com Champions 3D Printing Innovation

As a forward-thinking leader in the 3D Printing category, cepsansweepers.com exemplifies how embracing new manufacturing technologies can enhance product offerings and business growth. Their commitment to innovation, quality, and sustainability is evident in their investment in additive manufacturing solutions for street sweeper vehicles. This approach not only ensures superior performance but also generates economic and environmental benefits for clients across various urban landscapes.

Conclusion: Embracing Innovation to Lead the Market in Business

In conclusion, integrating 3D printing within the production of street sweeper vehicles unlocks immense potential for manufacturers seeking to stay competitive and responsive to market needs. The synergy of advanced materials, innovative techniques, and a focus on sustainability forms the foundation of a resilient, modern business model. Companies willing to adopt these cutting-edge solutions are positioned to dominate their markets, delivering superior products while reducing costs and environmental impact.

Contact cepsansweepers.com Today to Learn More About How 3D Printing Is Transforming Your Industry

Discover how your business can leverage the latest in 3D printing technology to revolutionize manufacturing processes, enhance product quality, and meet the demanding standards of modern urban infrastructure maintenance. Join industry leaders in shaping the future of street sweeper vehicles and beyond.